THE RIGHT TOOL MAKES ALL THE DIFFERENCE

SYNCHRONOUS LIFTING SYSTEMS

Hydraulic lifting capacities range from 10-ton to 1000-ton

Controlled lifting pumps surpass independently operated ones for precise movement of heavy objects with multiple lifting points. By managing oil flow to each cylinder, these pumps ensure accurate positional control, enhancing safety and productivity by eliminating manual intervention. Synchronous Lifting Pumps, like EVO SyncLift Systems, utilize high-pressure hydraulics and PLC controls for centralized monitoring, achieving a 0.040-inch accuracy between lifting points. Split-Flow Hydraulic Pumps offer a safe and economical alternative for lifting applications on multiple points, maintaining even load distribution during lifting and lowering operations through controlled flow to each outlet.

SYNCHRONOUS LIFTING SYSTEMS

0 – 1500 TON Capacity

SYNCHRONOUS LIFTING SYSTEMS

Synchronous Lifting Systems – Results traceable back to NIST: For lifting and lowering applications with multiple points, controlled lifting pumps are a far better alternative than using independently operated pumps.

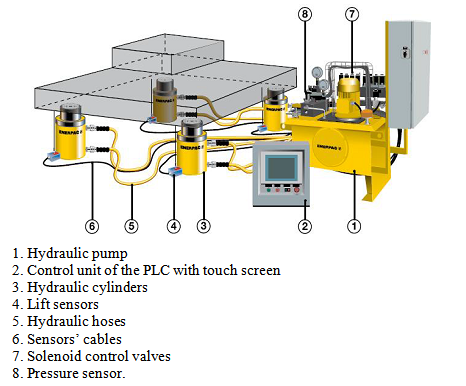

Synchronous Lifting Systems (SLS) is a technique used to lift heavy loads in a precise and synchronized manner. It involves the use of multiple hydraulic jacks, which are connected to a computer-controlled system. The system allows for the lifting and lowering of each jack to be synchronized, ensuring that the load remains level and stable during the lifting process.

SLS is particularly useful for applications where heavy loads need to be lifted and moved with a high degree of precision and control, such as in the construction of bridges, buildings, and other large structures. The system can be used to lift loads weighing several thousand tons, and the synchronization of the lifting process minimizes the risk of damage to the load or the surrounding structures.

Overall, SLS is a highly efficient and effective lifting technique that has revolutionized heavy lifting in many industries. It has become an essential tool for many large-scale construction projects and has contributed to the safe and successful completion of many complex engineering projects.

Sensor Extension and Cylinder Stroke

The sensor extension is different from the Cylinder stroke value. The sensor extension is hooked to the load, and it has a value even when the Cylinder is collapsed.

The potential applications of this system are numerous synchronized lifting levering, pushing, pulling and positioning using computer technology and high-pressure hydraulics has become popluar in many industries around the world.

The lifting or lowering capacity of this system is unlimited. By adding more or larger hydraulic cylinders to the setup, the system allow jobs of 50,000 tons and more to be lifted with a high-level of safety and accuracy.

Computer controlled lifting and lowering system

- Personal computer based control unit with user-friendly Windows interface

- Digital control of the lifting process accurate to + – .04” [1mm] between leading and lagging lifting points

- Multiple lift point capability, from 2 to 24 points

- Data recording, graphic presentations and print-out capability

- Automatic stop at pre-set stroke or load limit

Setting new standards in precision and control

- Accuracy

– Digital control of the lifting process accurate to + – .04” [1mm] between lifting points

– Real time, on screen monitoring provides complete lift status

- Safety

– Digital control programmed for “Fail-Safe” operation

– Actual load movement is measured

– Pilot-operated check valves automatically hold cylinder pressure in the event of hose failure - Serviceability

– Worldwide network of Enerpac Authorized Service Centers

– Uses easy-to-service, standard Enerpac components - Ease of Operation

– One person operation

– PC-based controller runs in Windows environment

– Point-and-click mouse control

– Multi-lingual data screens available

– Standard Enerpac 10,000 psi single- and double-acting cylinders